Repair guide for your board, choosing between an Epoxy or Polyester repair kit?

First of all, what is the difference between an EPS and PU board?

If you need to repair your board, the The first thing to know is whether your board is made of EPS or PU because these 2 types of “core” (core of the board) will tell you if your board is made of resin. Epoxy or resin Polyester . Indeed, boards whose core is EPS (Extruded Polystyrene) are always glazed with an EPOXY resin while boards with a PU (Polyurethane) core are glazed with POLYESTER resin. Therefore and so as not to be mistaken:

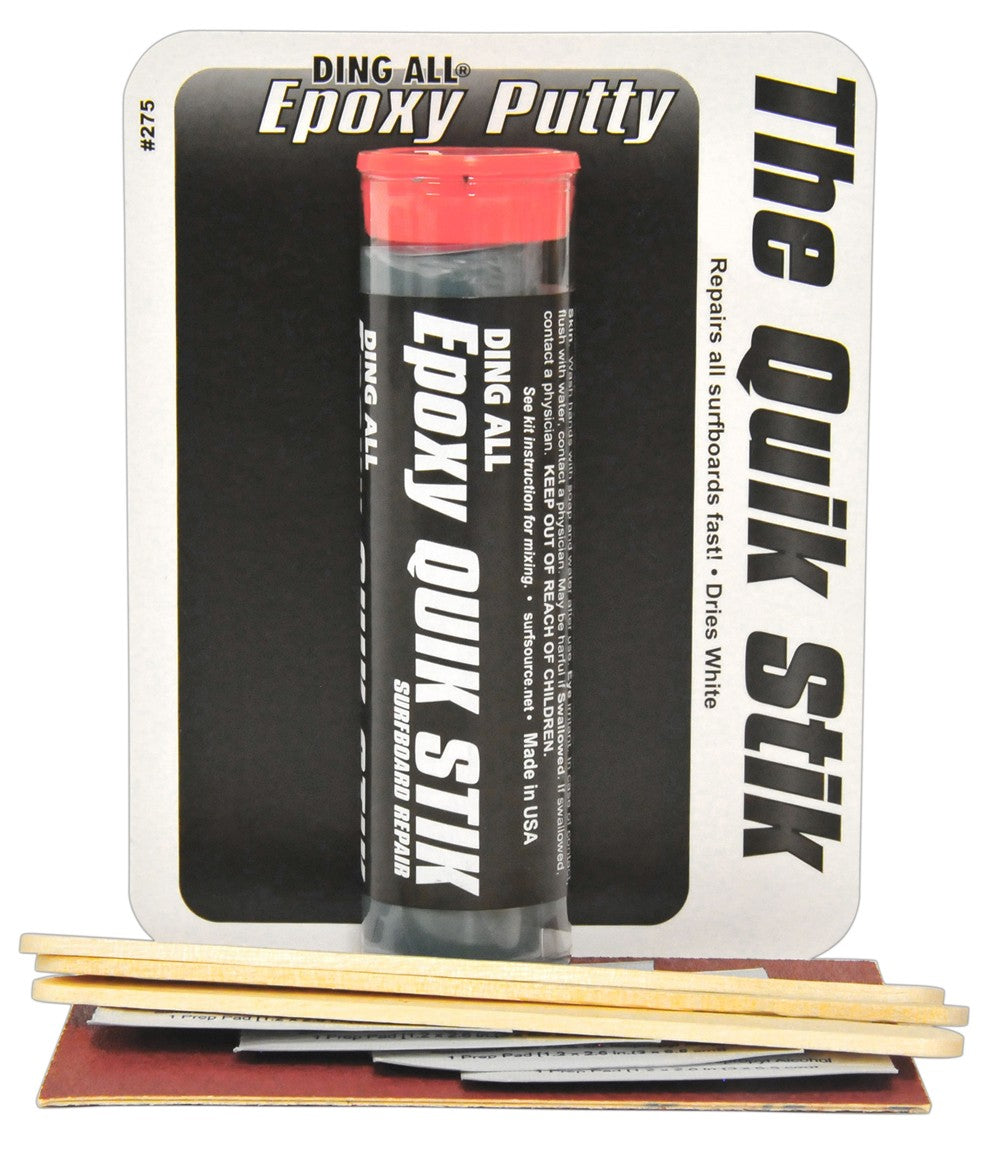

- EPS board = Epoxy resin = Buy an Epoxy repair kit

- PU board = Polyester resin = Buy a Polyester repair kit

If in doubt, ask a surf shop or a repairer/shaper.

NB: When in doubt or in an emergency , always choose the Epoxy kit because it will not risk burning and damaging your board. Conversely, the polyester repair kit on an EPS/Epoxy board will burn the foam block and the Epoxy resin!

A little history, information, technique and culture:

Historically the boards in PU / Polyester (PU foam block + fiberglass fabric + Polyester resin) are the first modern boards to appear on the market (at the beginning the boards were made of wood), this manufacturing process dates from the end of the years 50's (Hobie Alter and Gordon Clark shaped the first PU + Polyester boards at the end of the 50's) and is still the simplest and most widespread manufacturing method on the market. It is not very expensive, not very complicated, allows you to make all types of boards and to adjust the strength of the 'glass' (fiberglass fabric + Polyester resin) depending on the type of board you are surfing (glass thick for a longboard or light for a shortboard). PU and Polyester resin offer a certain flex and a fairly traditional feeling to the boards, it is often the preferred construction of pro shapers and pro surfers who appreciate the predictable behavior of PU boards. In big waves or hollow waves as well as in choppy PU boards are very forgiving, have pleasant inertia, good grip (a little heavier) and a more docile behavior much appreciated by surfers. Traditional longboards are generally all made of PU/Polyester as well.

Boards EPS (EPS foam block + fiberglass and Epoxy resin) arrived later on the surfboard market (originally windsurf boards used this manufacturing process). EPS/Epoxy boards are often lighter, more responsive, more resistant to dents and float proportionally more (for the same volume, an EPS foam block floats more than a PU foam block). This increased buoyancy makes paddling easier (but not ducks). EPS will allow surfers to have more reactivity, recovery and speed but they have a stiffer, more rigid behavior and are less forgiving of mistakes. These boards are often well suited to small waves and/or for starting surfing because they are easier to paddle thanks to the increased flotation and are solid (less sinking when you start if you hit your knees on the deck). the board). High performance shortboards in EPS/Epoxy with, for example, carbon reinforcements are also on the market, for demanding surfers who want a responsive, light board that is a little more solid than a PU board.

Find here all our repair kits for Epoxy or PU